Concrete Optimization

Click any image to access the journal article explaining this research.

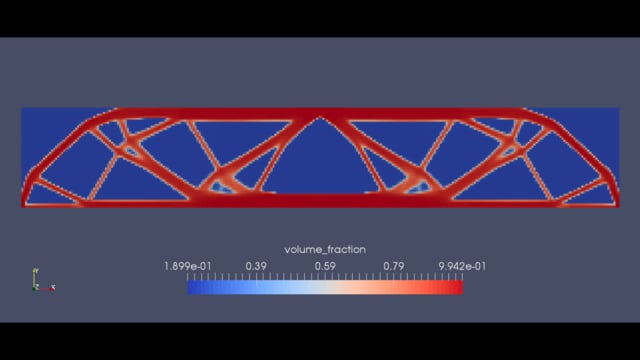

Topology optimization is an exciting tool for generating efficient structural design, yet there is little experimental confirmation of their efficacy in Civil Engineering applications. For my thesis, I fabricated and tested concrete beams designed with a stress-based topology optimization algorithm.

For our experiment's load case, we selected the top portion of a hammerhead highway pier, inspired by Dr. Andrew Gaynor's research on bilinear truss-continuum topology optimization.

3-point load beam optimization

This video shows how topology optimization generates efficient forms through iteration using a gradient-based algorithm.

To make the highly non-linear concrete molds, we used a 3-axis CNC milling machine to carve the formworks out of structural styrofoam.

Formworks were sanded and lined with white petroleum jelly to reduce the effect of residual porosity and ease the release of the concrete members.

In order to add reinforcing steel to one of our designs, we asked MIT's blacksmith to custom-bend 3 pieces of number 4 rebar to fit into our molds.

We made 4 batches of 5,000 psi concrete to fabricate the specimens

The concrete was allowed to cure for 28 days to reach maximum strength. It was maintained in a humid environment to avoid water loss and microcracking

We made 15 concrete members and took samples from each concrete batch for tension and compression tests. They will be tested to find out if they perform as our algorithms had predicted.

Above are two different designs we developed with our optimizer.

The concrete members rested in a water bath until they reached their full strength. Results from the experiments are found in the publication, Topology-optimized design, construction and experimental evaluation of concrete beams